Blocking and Bracing

Total Incapsulation

Six foam pads in a box is the simplest example of blocking and bracing. It has solved many packaging problems for decades.

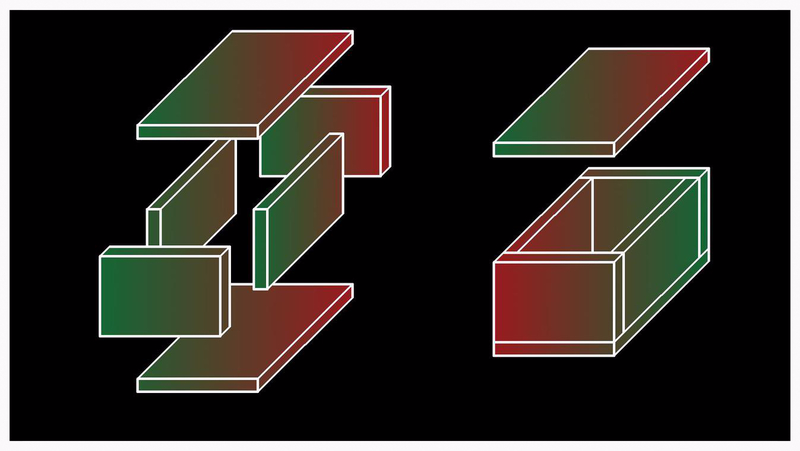

Blocking and bracing is most likely the original foam packaging concept. It's design is simple and it is price effective. It can be a little cumbersome depending on how many pieces are required, but sometimes keeping it simple and cheap is prudent.

Blocking and bracing is a process of positioning foam pads, blocks, and shapes in stratigic locations that demobilize the product in the center of its shipping container. None of the foam is glued or assembled together.

The container, the product, and the shape of the foam work in conjunction to prevent the foam from shifting into an undesirable position that could cause damage to your package. There is a very simple test that will help you decide if our blocking and bracing design will be effective for your product. Put the package together and ask your self which piece or pieces of foam cushions and protects the product when it lands on its top side and then which pieces protect the bottom? ask the same question about the two side and the two ends. If there is protection in all six directions your on the right track.

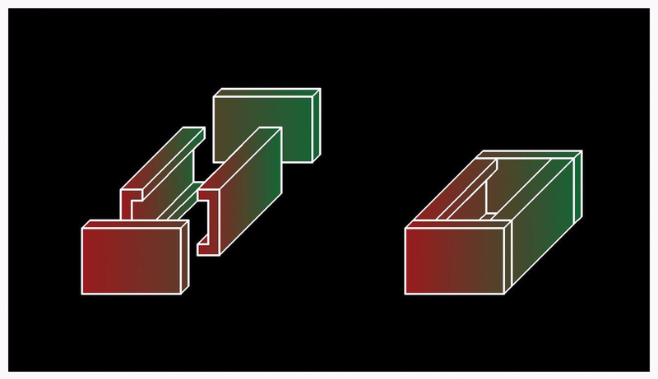

U-Channels & Pads

By using two U-shape profiles, we have decreased the number of foam pieces to four. Two of them are identical U-channels and two are identical pads. This concept is less expensive because it uses less foam and there are only two seperate pieces to make. That is only two set ups and longer runs which always keeps the price down. Look at this design and ask your self, does this protect the product in all six directions of its container? Then ask yourself, does it sufficiently protect it in each direction? If you think the answer is no then you might want to modify the u-shape or try a different packaging concept. No worries though, we can help find the best design for your product!

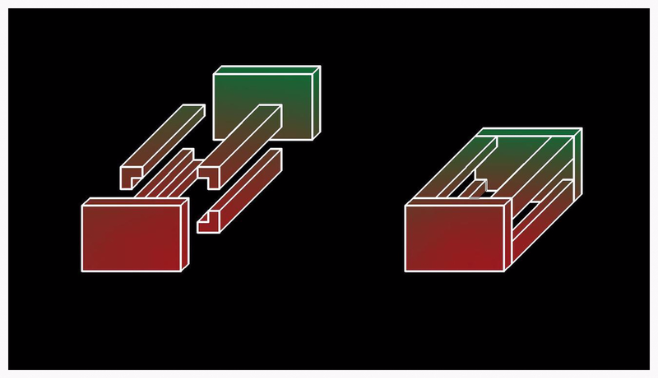

L-Shapes & Pads

This packaging concept is utilizing six pieces to protect, but there are only two separate pieces to run,and it uses less foam. This concept is generally less expesive than previous concepts mentioned. The percentage of labor on smaller parts is significantly higher than larger and less detailed parts. That means that even though we are using considerably less foam, the price will not drop proportinally due to the additional labor that is required in fabricating small parts. There is a point of diminishing returns. Another consideration is how much time it will take to package your product. This is a cost that is often ignored. If you can't package them as fast as you can make them, that can cost a small fortune. Always consider this when determining your true packaging cost.

In this case we are using less foam by creating four l-shape profiles