How is Extruded PE Made?

Extruded Polyethylene is our most popular foam material at Technifoam. This material is extruded into a long continuous piece of foam that cools on a long conveyer at the end of the coveyer the foam is cut to a determined length. This piece of foam is referred to as a Plank.

PE foam can also be extruded into thin and long lengths that are rolled up at the end off the conveyer to create a roll of PE foam.

As we all know it floats very well. A swimming noodle is an excellent example of Extruded PE. The only difference is the noodle is extruded into a round shape instead of a plank which is a long rectangle sheet that is intended to be cut to various shapes.

Extruded PE is less expensive than the other PE foams. PE does have one limitation. It has a slightly abrasive surface where it has been cut. If you cannot afford any abrasion on your product, then you should consider one of the other PE materials to accomplish your goal.

Specifications

Raw Material Size

Extruded planks are manufactured in various thicknesses. The most common sizes are 1", 2" and 3" thick. These planks can be sealed together to create thicker laminated plank.

Medium density plank are manufactured 48" wide which this can not deviate where as the length can be special ordered shorter or longer than the standard 108" plank.

High density planks such as 4,6 and 9 pound material are manufactured 24" wide and 108" long.

Densities

What is Density

The density is simply how much a 12" x 12" x 12" piece of foam weighs.

PE comes in a variety of densities ranging from 1.2 pound to 9 pounds per cubic foot

The most popular density is 1.7 pounds. Like all other foams the higher the density, the more expensive the foam will be

Grades

Grade A -- Standard

Grade B -- Static Dissipative

Grade C -- Fire Retardant

Grade D -- Static Dissipative and Fire Retardant

Innovative Options

Polylaminate Plank

Polylaminate (PL) planks are fabricated by sealing multiple layers of roll foam together to create a desirable thickness and length that will maximize your yield and minimize your cost. Because these planks are fabricated from stock sized rolls, it makes special material much more accessible and quicker to get.

Repro Plank

Repro is a Polylaminated product.

Up to 65% of Repro's content is reclaimed recycled material of many different densities and colors. For color consistency the material is died black.

In the past, going green could cost you more money. Not now! Repro is the least expensive PE foam available and it does an excellent job for most packaging applications. Now you can save money, and still be green.

No wonder this is our most popular foam!

Hingelock / Repro Plank

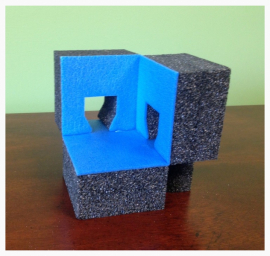

Another type of Polylaminated planks is Hingelock. This foam is fabricated by thermal sealing a thin high density (blue) PE foam to a lower density Repro (black) foam.

A foam hinge can be created by cutting through the lighter foam and stopping the cut prior to cutting into the higher density foam. The high density material works as a durable hinge that allows the lower density foam to be repositioned in a perpendicular direction that will protect your product. This feature eliminates the costly factor for assembly. There are countless benefits and applications for this material.

This picture is an example of how the hinge works when fabricating corner protectors.

To see more hingelock designs, CLICK HERE!

Would you like us to quote an PE project? Request a Quote!