Fabricating Process

Precision is Key

Our CNC automated hot wire cutting line allows us to cut a wide variety of parts in a very efficient manner. This machine uses heated wires to cut foam into various shapes. Anything from sheets, pads, and profiles can be cut with this machine. Tooling is not required so there is no upfront cost, and it cost nothing to change. Give EPS a try.

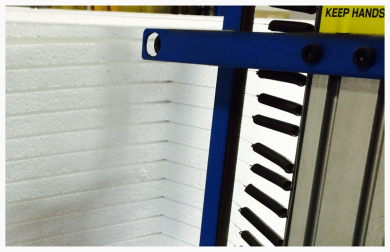

Downcutting

If you want a trimmed square sheet or pad, the stack of sheets are moved to the downcutter. The downcutter has a grid of wires that are carefully set to the desirable width and length of the sheet or pad that is ordered. The grid of hot wires move vertically up or down to melting the foam in two directions. When the wires finish cutting, a stack of evenly size pieces remain. The scrap around

the edges is removed and the foam pieces are packaged for shipment.

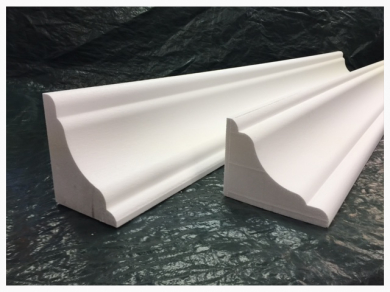

Profiles

Our CNC will also cut specialty designed shapes. The same harp of hot wires that cut flat sheets can simultaneously move in two directions. It follows the routing from an AutoCAD drawing. We can virtually cut any two dimensional shape.

When we program the machine to cut a simple 6"circle the machine travels in a circle pattern but it cuts a 6" cylinder that is the length or width of the billet. These cylinders are removed from foam shaped scrap cocoon and they are placed on the downcutter to cut the length or thickness of the profile. The scrap is removed around the edges of the shapes and the profiles are packaged for shipment.