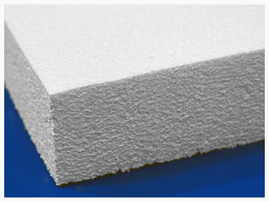

Expanded Polystyrene

How is Expanded Polystyrene Made?

Expanded Polystyrene is made by injecting thousands of polystyrene beads into a rectangular or special shaped mold. The polystyrene beads are heated with steam. The bead will then soften and expand up to forty times its original size. At first the beads expand outwardly inside the mold until there is no more room. Then it expands inward until all the beads fuse together to create an Expanded Polystyrene Billet or shape.

Polystyrene foam was invented during World War II. Dow Chemical Company was trying to invent a flexible electrical insulator. During this process they made a mistake and they invented Polystyrene. It was a very fortunate accident that proved to be very profitable. The Dow Chemical Company introduced Polystyrene products to the United States in 1954. They called it Styrofoam. This brand name has become a household word that means foam. It is similar to how people refer to the Kleenex brand when they need a tissue.

Applications:

Packaging Foam

The Packaging industry is a strong market for EPS, and especially for us! EPS is the least expensive packaging foam available. It is a very effective packaging material that can be designed and fabricated to withstand a few drops. Some products are not handled as many times as others. The fewer times a product has an opportunity to be dropped, the more likely EPS can protect your product. Why pay for foam that will give you countless drops, when your product will only be handled a few times?

When shipping products in bulk packages, EPS can be fabricated to separate various components to prevent them from rubbing, vibrating, or knocking up against one another. Sometimes a simple EPS pad, placed in the correct spot, can solve your packaging problem for a minimum price.

Due to the success of the internet, more and more items are being shipped via UPS or FedEx. Many companies have a tendency to rule out EPS before they even consider it as a possibility. They tend to choose more expensive foam to ensure their products wellbeing. However, if you are on a budget, or even over budget, you should at least consider EPS and allow us to design a package that may save you a considerable amount of money. We always insist that our customers test our designs before committing to them. This ensures that they work and that you will be happy with the end result.

Floatation Foam

About 98% of Expanded Polystyrene material is air. This makes EPS very light, which also gives it great buoyancy. EPS has been used to keep many products afloat for decades. Many boats are filled with EPS to ensure they will not sink. EPS is also encapsulated into plastic tubs to create floatation devices for docks. It is used in toys and fishing gear. There are numerous possibilities for floatation applications with this material.

Insulation and Construction Foam

EPS sheets are used to insulate walls, to taper roofs, and to create decorative architectural shapes such as crown moldings, pillars, and archways. Insulation and construction are the primary industries that drive the EPS market.